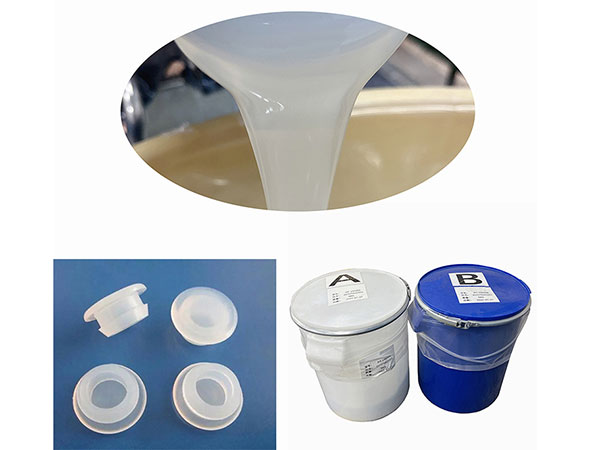

Precipitated LSR for Miscellaneous Parts (Injection Molding)

Applications

This liquid silicone rubber (LSR) is utilized for manufacturing various types of smartwears, watch bands, earplugs, adult toys and other miscellaneous parts.

Features

- Rapid vulcanization, good dimensional stability and processability;

- Non-toxic and safe, food grade;

- High tear strength, non-yellowing and good flowability;

Approvals

ROHS, REACH, FDA, CA65, EN71-3, EN14372, PAHS, PFOA, CPSIA, etc.

Test

Rheometer test, 120℃, 5min

Technical Data

- Model:

HT-L3100A/B - Appearance: Translucent

- Viscosity: 10W-20W

- Hardness (Shore A): 10

- Density (g/cm3): 1.06

- Tensile strength (Mpa): 4

- Elongation (%): 800

- Tear strength (K N/m): 10

- Model:

HT-L3200A/B - Appearance: Translucent

- Viscosity: 20W-30W

- Hardness (Shore A): 20

- Density (g/cm3): 1.08

- Tensile strength (Mpa): 5

- Elongation (%): 760

- Tear strength (K N/m): 15

- Model:

HT-L3300A/B - Appearance: Translucent

- Viscosity: 30W-39W

- Hardness (Shore A): 30

- Density (g/cm3): 1.09

- Tensile strength (Mpa): 6

- Elongation (%): 700

- Tear strength (K N/m): 20

- Model:

HT-L3400A/B - Appearance: Translucent

- Viscosity: 40W-49W

- Hardness (Shore A): 40

- Density (g/cm3): 1.1

- Tensile strength (Mpa): 7

- Elongation (%): 650

- Tear strength (K N/m): 20

- Model:

HT-L3500A/B - Appearance: Translucent

- Viscosity: 40W-49W

- Hardness (Shore A): 50

- Density (g/cm3): 1.1

- Tensile strength (Mpa): 7

- Elongation (%): 600

- Tear strength (K N/m): 20

- Model:

HT-L3600A/B - Appearance: Translucent

- Viscosity: 40W-49W

- Hardness (Shore A): 60

- Density (g/cm3): 1.13

- Tensile strength (Mpa): 7

- Elongation (%): 500

- Tear strength (K N/m): 20

- Model:

HT-L3700A/B - Appearance: Translucent

- Viscosity: 40W-49W

- Hardness (Shore A): 70

- Density (g/cm3): 1.14

- Tensile strength (Mpa): 6

- Elongation (%): 400

- Tear strength (K N/m): 10

- Model:

HT-L3800A/B - Appearance: Translucent

- Viscosity: 40W-49W

- Hardness (Shore A): 80

- Density (g/cm3): 1.15

- Tensile strength (Mpa): 7

- Elongation (%): 200

- Tear strength (K N/m): 8